Operating a restaurant is an expensive proposition. Between supplies, employees, equipment, and often franchise fees, a typical restaurant is left with pretty small margins. So when disaster comes around, it can really hurt.

You can take simple building automation steps to mitigate risk, however, without major investments. A simple example is automated start-up and shutdown of hot kitchen equipment like fryers, ovens, and grills. Kitchen staff work long hours and a tired employee can occasionally forget an important task that could result in a dangerous and expensive situation.

However, auto-startup and shutdown is just one way to protect yourself from disaster using automated monitoring and control. ControlByWeb can help you do everything from automated door locks to monitoring refrigerators and freezers.

Full Automation System

- Create a complete control system for your restaurant

- Real-time monitoring

- Smart email/txt alarms

- Data logging

- Monitor doors and control cooking equipment, HVAC, and more with Task Builder and Scheduling

- Monitor important assets like walk-in coolers, used cooking oil tanks, etc with nearly any sensor

- And much more…

Problems

Temperature Monitoring & Record Keeping

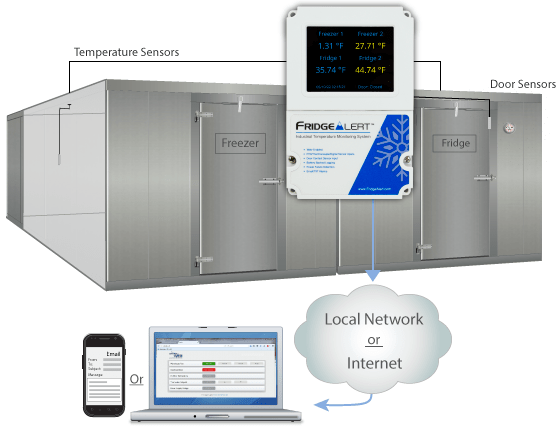

Monitoring temperature manually is time consuming and can result in record keeping failures or errors. Lapses in monitoring is common and equipment problems while your staff is away can result in expensive losses.

Human Error

Tired kitchen staff work hard during long nights. They can easily forget to lock the doors at night, shutdown a fryer, or miss the morning start up. Human error can be common, dangerous, and very costly.

Alarm Overload

Most monitoring solutions don’t offer smart alarms without upgrading to more expensive packages. Slight temperature fluctuations can result in too many alerts which can cause staff to ignore them altogether.

ControlByWeb™ Solutions

Smart Cooler Monitoring & Data Logging

Automated walk-in cooler monitoring and temperature data logging means you can access reports whenever you need to, and are always immediately alerted to problems with your equipment before it’s too late.

Automated Startup, Shutdown, & Locking

Our affordable and reliable 400-Series controllers feature no-code programming with Task Builder and scheduling so you can easily automate door locking, the start-up and shutdown of cooking equipment, and nearly anything else.

Smart Alarm Logic

Our controllers are built with on-board logic powerful enough to create intelligent alarms without code. It’s easy to eliminate useless notifications so staff are only alerted to real problems.

FREE RESTAURANT BUILDING AUTOMATION CONSULTATION

Case Study: Meadowbrook Restaurant Co.

Joe Sharp is the Area Facilities Manager for Meadowbrook Restaurant Co. He’s in charge of every aspect of the companies’ buildings and making sure their equipment is fully functional. He does it all with the help of ControlByWeb expandable I/O controllers.

Sharp has undertaken the task of automating his facilities as much as he can. His goal is to create a safe, efficient workplace for restaurant staff, and to make managing multiple restaurants faster and easier. With ControlByWeb, the possibilities are nearly as big as his imagination.

His first task was to monitor walk-in freezers and refrigerators. Initially, he installed a competitor’s temperature monitoring product. However, trouble arose when they received so many false temperature alarms that his staff began to ignore them. Eventually, they had a real equipment failure that went ignored, causing them to lose their inventory in a freezer. Sharp estimates that the loss cost them more than $10,000.

Temperature Monitoring

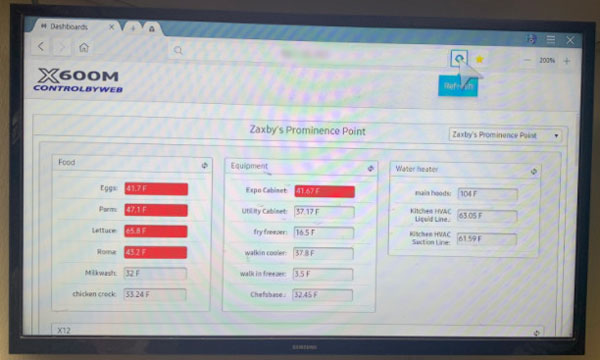

The mission quickly became to find a temperature monitoring system that had enough logic to ignore defrost cycles, typical door openings, etc. He found his answer in the X-600M from ControlByWeb. He is now able to monitor multiple coolers, log typical temperature fluctuations from normal operation, program alarm logic that only sounds for real problems, and add in a variety of building automation for safety and preventative maintenance.

Cooler Health

A former refrigeration technician, Sharp simply taped temperature sensors to his coolant lines on the roof using the same X-600M to monitor his freezer/refrigerator performance. Now he knows if his coolers need maintenance a lot sooner, and he can distinguish between a door left open on a walk-in and equipment failure. Similarly, he runs his building HVAC through his X-600M, giving himself a remotely accessible thermostat.

Automatic Equipment Shutoff & Lock Control

To prevent human error from causing a dangerous situation, Sharp turned to the kitchen equipment. He uses the same X-600M to automatically turn on and shut off all his hot cooking equipment each morning and every night respectively. He doesn’t have to worry about a mistake causing a building fire. Likewise, the restaurant doors automatically lock and unlock at preset times. If his system doesn’t perform as expected, he knows about it while he can still fix it quickly.

Complete Building Automation

Sharp is looking for more ways he can use ControlByWeb controllers to automate his restaurants. He’s doing something new all the time. Some of the things he’s already automated include:

- Building lights

- Irrigation system

- Water flow & leak monitoring

- Valve control

- Bulk cooking grease tank level monitoring

He’s gotten very creative with displays as well, mounting televisions that display the current temperatures and equipment status to kitchen staff and general managers. For Sharp, our X-600M is his choice due to the dashboard feature and sheer I/O capacity. He says, “I told my [boss] at one point ‘I don’t think there’s anything that ControlByWeb can’t do.'” We’re still waiting for his call that he’s found a limitation we can’t overcome.

For most restaurant automation tasks, our X-400 is our ideal controller. The newer X-400 features most of the same capabilities, but with our improved Task Builder and ControlByWeb Cloud compatibility.

Contact us to discuss which controller is best for your restaurant automation needs.

Testimonial

As the facilities manager and refrigeration technician for a 6 location restaurant chain in the Atlanta area, I needed a means of monitoring my critical equipment temperatures. I used several different systems that would alert me above a certain threshold, but found that through daily operations there were many reasons why temps would break that threshold for a short time and then return to normal. There wasn’t a problem, that was a normal ebb and flow of equipment operation. False alarms become the norm and when a problem truly does manifests itself, the system that cried wolf doesn’t receive the attention it should.

In my journey of automation I found ControlByWeb. I installed ControlByWeb in one location as a test. The installation was simple and before long I had 12 temperature probes in place and was recording data. Then the fun began, through several tech support calls I was taught how to setup parameters and alerts that would eliminate false alarms completely. With not only threshold alerts but delays, we used the data to determine what normal parameters looked like and set alerts just outside of them. No more false alerts during defrost cycles, truck deliveries, or restocking with doors open. When CBW alerts me, there is a problem.

I gradually created more and more facility automation and supervision with ControlByWeb. The powering on and off of cooking equipment eliminates the risk of staff failing to turn them off and starting a fire. Automatic locking and unlocking of doors, controlling my building lights, replacing my HVAC thermostats, monitoring bulk oil tank levels, controlling my irrigation zones, monitoring the gallons or water per minute flowing into my facility and automatically closing a valve at the main inlet if we start flowing outside of norms to prevent flooding and waste. Temperature sensors on specific refrigeration lines give me real-time pressures as if I have service gauges recording equipment health all the time.

I told my owner at one point “I don’t think there’s anything that ControlByWeb can’t do.”

I claim myself to be an automation junkie, and ControlByWeb has really taken what’s possible to another level. I’ve yet to concoct a scheme that ControlByWeb hasn’t brought to reality.

Joe Sharp

Meadowbrook Restaurant Co.

Area Facilities Manager