Level Monitoring & Control

Our controllers and level sensors provide a complete level monitoring solution for liquids and solids. They’re accessible on local or remote networks.

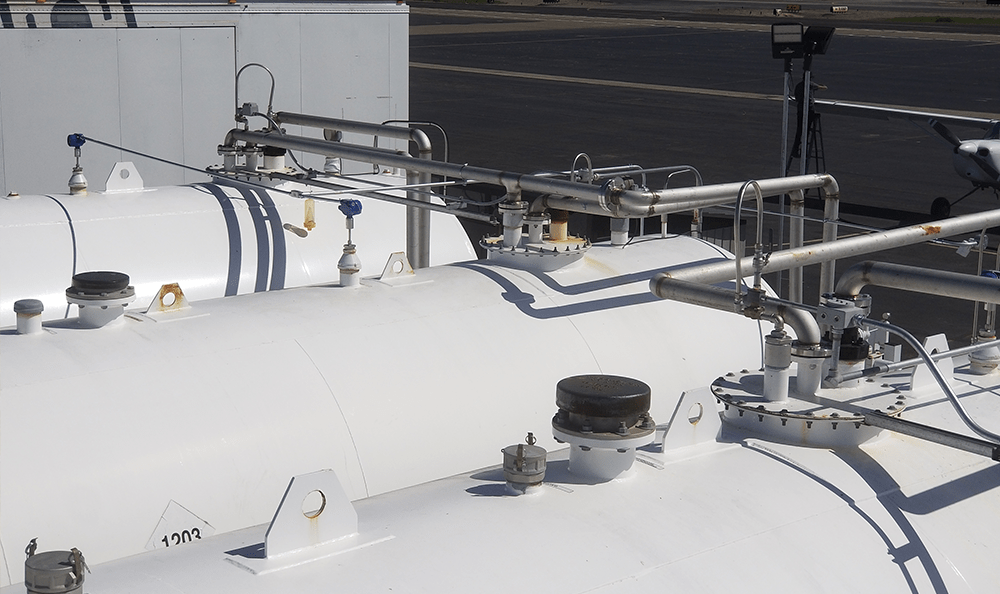

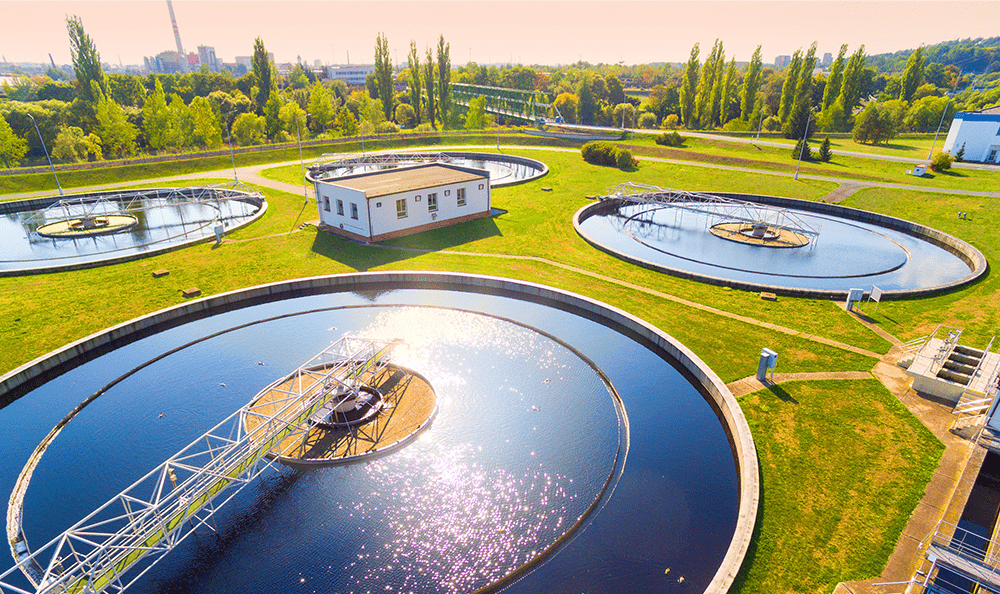

Local or Remote Level Monitoring & Tank Monitoring

We make level monitoring and control, whether local or remote, reliable and affordable with sensors and controllers that last for years with little to no maintenance. Our industrial-grade hardware and easy-to-use programmable interface enables municipalities, growers, systems integrators, and more to quickly deploy accurate and durable control systems almost anywhere.

Monitor liquid levels and solids with four different types of monitoring technologies: non-guided radar, ultrasonic, float, and pressure. Whether you have an IBC tank, tote, silo, or chemical injection tank, ControlByWeb has the best level monitoring system for your application.

Features

- Remote monitoring of multiple tanks

- Email & text alerts for user-defined thresholds

- View and send logged data

- No code on-device logic

- API for sending data to other control systems

- No cloud required

Related Applications

Common Level Problems

Inaccurate Sensors

Level sensors can often struggle with process conditions, scaling issues, and physical container characteristics that render measurements inaccurate.

Difficult Controller Programming

Controllers traditionally rely heavily on programming languages such as ladder logic to build control logic, often requiring paid help from specialists.

Poor Scalability

Level sensors can often struggle with process conditions, scaling issues, and physical container characteristics that render measurements inaccurate.

ControlByWeb™ Solutions

Reliable Sensors

Our diverse sensor lineup means we have what you need almost every time, making it easy to overcome difficult process conditions and media characteristics.

Easy Task Builder

Our Task Builder allows complex control scenarios with a few clicks of the mouse. While we support scripting, no code is required to program your level controller.

Right Solution

ControlByWeb I/O devices scale to handle any size system. We handle small and medium control effortless and pair nicely with larger control systems.

Sensor Types & Applications

Ultrasonic

Ultrasonic sensors are ideal for liquid level monitoring and measurement with few application challenges and where budget is a priority. Ultrasonics use sound waves to detect a level surface and work well with reflective liquids like water. Distance to the surface is based on time of flight whereas the speed of sound is a known variable.

Float

Float sensors are for liquid level measurement and typically use magnets in the float and in the float guide or stem to determine the level surface. Our float level sensors are designed for use in hazardous locations and work great in oil and gas applications. They’re even capable of interface level measurement with dual floats.

Non-Guided Radar

Radar sensors use microwaves at varying frequencies. This is another time of flight measurement technology as the speed of the microwaves through the air is known. Radar sensors are better in difficult liquid level monitoring applications and is the clear choice for solids.

Pressure

Submersible pressure transducers are for liquids and do well in deep wells where sound and radar waves cannot reach. They’re common in water wells and lift stations. They work by measuring the head pressure above the sensor and are scaled by the density of the liquid.