Water/Wastewater Monitoring & Control

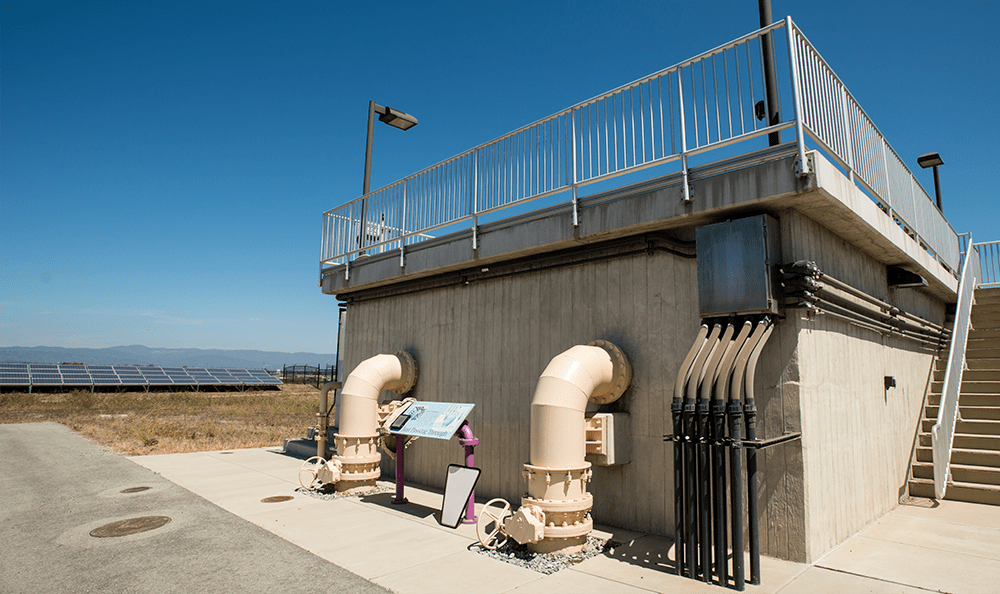

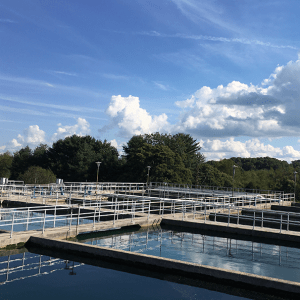

I/O controllers for water, level, and pump control in the water/wastewater industry. Control solutions for water treatment plants, wastewater treatment plants, irrigation water systems, and water pumping stations.

I/O Experts for the Water/Wastewater Industry

Our programmable I/O devices are perfect for water projects of all kinds. Our customers use our controllers for clean water, raw water, irrigation, and wastewater applications large and small. We focus on manufacturing industrial-grade I/O with inherent flexibility and affordable reliability.

ControlByWeb devices are easily programmed in a no-code setup menu that is built into the device itself. The non-proprietary platform communicates using industry-standard Modbus TCP/IP and a variety of other open-code languages to ensure maximum compatibility. They require no cloud software or Internet connectivity to function as a programmable logic controller for nearly any application.

These attributes make our I/O modules ideally suited for the water/wastewater industry. Critical control functions demand reliability, varying scopes require flexibility, and the vast array of aging infrastructure and new technology makes our open platform a big advantage.

Scalable I/O Solutions

Our expandable I/O modules let you mix and match to create your ideal control solution. Our devices are used as stand-alone controllers, as RTUs in larger control systems, or as a process control system. Whether you’re installing a simple duplex lift station or a large treatment plant, ControlByWeb is a great fit.

Remote Ready

All you need to view your control settings and process data is a web browser. Connecting your device to the Internet will allow you to monitor and control your processes anywhere in the world. Our devices communicate using Ethernet and standard networking practices and equipment and will work with your private network, Internet service, or your cloud.

Rural Water Systems

Our devices are more affordable than similarly capable control devices. We make sure of it through the way we operate as a U.S. business, and through keeping our solutions simple and purpose-built. This means we offer greater access to process control for rural water systems that are traditionally plagued by lack of funding and water quality challenges.

One rural water treatment plant upgraded to our X-600M platform from their old SCADA system. It cost them a very modest $10,000 when they expected to spend $100,000. Learn more here.

Related Applications

Common Water Monitoring & Control Problems

Closed Proprietary Systems

Proprietary systems are unfortunately commonplace in the water industry, forcing budget strapped municipalities to upgrade more equipment unnecessarily.

Difficult Programming

Many organizations don’t have the technical staff to program industrial controllers and have to hire programmers to make any adjustments or program any replacement units.

Too Expensive for Rural Water Systems

Rural community water systems experience more water quality violations due to budgetary constraints and cannot afford expensive control systems.

ControlByWeb™ Solutions

Open Compatibility

Our devices use on-board logic that is accessed on a standard web browser and communicate with control systems via Modbus TCP/IP, XML, and other protocols.

No-Code Programming

ControlByWeb I/O modules can be programmed using drop-down menus to control relays, trigger email and text alerts, log sensor data, and more.

Affordable, Self-Contained Solution

Each module costs a few hundred dollars and makes water/wastewater control projects much more affordable for budget-constrained communities.